Soluble Salt

Soluble Salt is aqueous organic complexes of metal cations. These are used for decoration of polished or unpolished vitrified ceramic tiles. The technology facilitates decoration with pleasing colours and special effects. Being water soluble, softer shades can easily be obtained by diluting the solution with water.

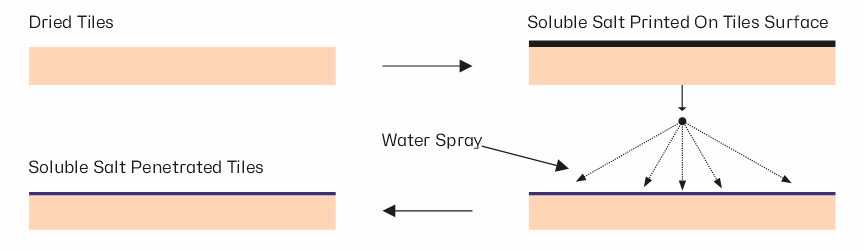

Working Principle

Under controlled conditions, these salts penetrate vertically into the green tile body to a required depth. The colours develop during the combustion process of kiln firing under oxidizing condition. Since the colours penetrate to a predetermined depth, tiles can be polished without losing the decoration. Thus the process is capable for decorating polished, unpolished and rustic tiles with consistency/uniformity.

Application Areas

Polished / Unpolished Vitrified Tiles

Packaging & Delivery

50 kg, 250 Kg & 1000 Kg HDPE drums

Schematic Diagram

Product Range

| Sr. No | Description | Product Code |

|---|---|---|

| 01 | Beige | FLC - 510 |

| 02 | Brown | FLC - 410 |

| 03 | Yellow | FLC - 466 |

| 04 | Blue | FLC - 927 |

| 05 | Black | FLC - 842 |

| 06 | Yellow Brown | FLC - 480 |

| 07 | Grey | FLC - 610 |

| 08 | Green | FLC - 526 |

| 09 | Dark Green | FLC - 527 |

| 10 | Dark Brown | FLC - 415 |

Direction For Use

Most common method to apply soluble salt is by silk screen. The printing paste needs to have correct viscosity, which must be achieved by suitable additives. For reference, the additives are used in following proportion by weight of soluble salt. However exact proportion may vary depending on application, pH value and specific gravity of the salts. The paste should be allowed to age for at least 30 minutes, preferably one hour before printing. It is advisable to consume the paste within 4-5 days. If kept in tightly closed containers, the paste can be stored for about 15 days.

Recommended Dosage

| Soluble Salt | - | 1000 g |

|---|---|---|

| Thickener | CTD AD 008 / CTD AD 010 | 35/40 g |

| Carrier | CTD AD 007 | 60g |